সম্প্রতি, কাঠের ডিবার্কার এর একটি বিশ্বস্ত সরবরাহকারী হিসেবে, আমরা সফলভাবে জাম্বিয়ার একজন ক্লায়েন্টকে একটি অনুভূমিক কাঠের ডিবার্কার সরবরাহ করেছি।

গ্রাহক পটভূমি

গ্রাহক জাম্বিয়ার কাঠ প্রক্রিয়াকরণ শিল্পে উদ্যোক্তা। তাদের লক্ষ্য ছিল নির্মাণ এবং আসবাবপত্র বাজারে উচ্চ-মানের প্রক্রিয়াকৃত লগ সরবরাহ করতে সক্ষম একটি অত্যাধুনিক সুবিধা প্রতিষ্ঠা করা।

এর জন্য, তাদের একটি কাঠের ডিবার্কার প্রয়োজন যা কার্যকর এবং পরিষ্কার প্রক্রিয়াকরণের নিশ্চয়তা দিতে পারে এবং অপারেশনাল খরচ কম রাখতে পারে।

গ্রাহকের চাহিদা

- পরিমাপযোগ্য সরঞ্জাম. বিভিন্ন আকারের লগগুলি পরিচালনা করার নমনীয়তা সহ একটি ডিবার্কার।

- বর্জ্য ব্যবস্থাপনা সমাধান। স্বয়ংক্রিয়ভাবে ছাল এবং ধ্বংসাবশেষ পরিচালনা করার জন্য একটি সিস্টেম, শ্রম খরচ হ্রাস করে।

- দক্ষতা এবং স্থায়িত্ব. ধারাবাহিক কর্মক্ষমতা সহ শুকনো এবং ভিজা কাঠ উভয় প্রক্রিয়াকরণ করতে সক্ষম একটি মেশিন।

বিক্রয়ের জন্য অনুভূমিক কাঠ debarker

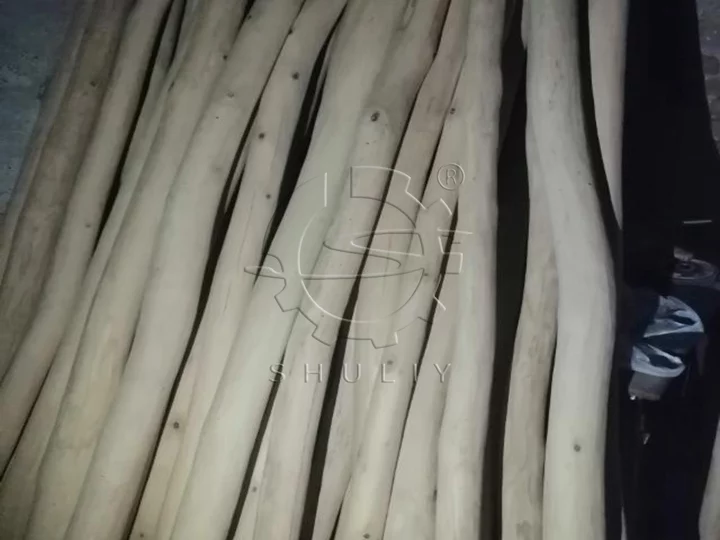

গ্রাহকের প্রয়োজনগুলি মূল্যায়নের পরে, আমরা একটি অনুভূমিক কাঠের ডিবার্কার সুপারিশ করেছি, যা একটি খাঁজ কাঠের ছাঁটাই মেশিন হিসাবেও পরিচিত। এই মডেলটি কার্যকারিতা, সক্ষমতা এবং উন্নত বৈশিষ্ট্যগুলির মধ্যে একটি নিখুঁত ভারসাম্য প্রদান করে।

কাঠ debarker বৈশিষ্ট্য

- U- আকৃতির খাঁজ নকশা. ডেবার্কারে স্পাইরাল কাটার দিয়ে সজ্জিত একটি U-আকৃতির ট্রফ রয়েছে, যা 500 মিমি ব্যাস পর্যন্ত লগ খোসা ছাড়ানোর জন্য আদর্শ।

- দ্বৈত সর্পিল কাটার। প্রক্রিয়াকরণ ক্ষমতা এবং গতি বাড়ানোর জন্য দ্বৈত সর্পিল কাটার সহ মেশিনগুলি নির্বাচন করা হয়েছিল।

- বর্গাকার গর্ত সিস্টেম। U-আকৃতির খাঁজে বর্গাকার ছিদ্র রয়েছে যা ডিবার্কিং প্রক্রিয়া চলাকালীন ছাল এবং ধ্বংসাবশেষের মধ্য দিয়ে পড়তে দেয়।

- ঐচ্ছিক পরিবাহক বেল্ট। ধ্বংসাবশেষ হ্যান্ডলিং স্বয়ংক্রিয় করতে, আমরা বর্জ্য ব্যবস্থাপনার জন্য ন্যূনতম কায়িক শ্রম নিশ্চিত করে একটি পরিবাহক বেল্ট সিস্টেম যুক্ত করার সুপারিশ করেছি।

চ্যালেঞ্জ এবং সমাধান

ইন্টিগ্রেশন উদ্বেগ

কাঠ প্রক্রিয়াকরণের যন্ত্রপাতিতে নতুন হওয়ায়, গ্রাহকরা নিশ্চিত ছিলেন না যে কীভাবে কাঠের ডিবার্কার তাদের সুবিধার মধ্যে মাপসই হবে। এটি মোকাবেলা করার জন্য:

- আমরা প্রদান করেছি বিস্তারিত পরামর্শ তাদের পরিকল্পিত সেটআপের সাথে মেশিনের সামঞ্জস্যের উপর।

- অফার করা হয়েছে কাস্টমাইজড লেআউট পরিকল্পনা, কিভাবে debarker তাদের কর্মপ্রবাহে একীভূত হবে তা চিত্রিত করে।

খরচ বিবেচনা

একটি নতুন সুবিধা শুরু করার জন্য গুরুত্বপূর্ণ আর্থিক পরিকল্পনার প্রয়োজন। এই বোঝা কমাতে:

- আমরা একটি প্রস্তাব নমনীয় পেমেন্ট ব্যবস্থা, পরিচালনাযোগ্য কিস্তিতে বিনিয়োগ ছড়িয়ে দেওয়া।

- অত্যাবশ্যক খুচরা যন্ত্রাংশ এবং সরঞ্জাম অন্তর্ভুক্ত, গ্রাহক দীর্ঘমেয়াদে রক্ষণাবেক্ষণ খরচ কমাতে পারে তা নিশ্চিত করে।

ডেলিভারি এবং ইনস্টলেশন

গ্রাহকের সুবিধার দূরবর্তী অবস্থান লজিস্টিক চ্যালেঞ্জ তৈরি করেছে। মসৃণ ডেলিভারি এবং সেটআপ নিশ্চিত করতে:

- নিরাপদ পরিবহনের নিশ্চয়তা দিতে আমরা নির্ভরযোগ্য শিপিং অংশীদারদের সাথে সমন্বয় করেছি।

- ইনস্টলেশন পরিচালনা, কর্মক্ষমতা পরীক্ষা পরিচালনা এবং সঠিক অপারেশন এবং রক্ষণাবেক্ষণের বিষয়ে গ্রাহকের কর্মীদের প্রশিক্ষণের জন্য একটি প্রযুক্তিগত দল পাঠিয়েছে।

ফলাফল

অনুভূমিক কাঠ ডিবার্কার থেকে গ্রাহকের নতুন সুবিধা দ্রুত উপকৃত হয়েছে:

- বর্ধিত দক্ষতা. মেশিনের দ্বৈত সর্পিল কাটারগুলি লগ প্রক্রিয়াকরণের গতিকে উল্লেখযোগ্যভাবে উন্নত করেছে।

- স্ট্রিমলাইন অপারেশন. পরিবাহক বেল্ট সিস্টেম বর্জ্য ব্যবস্থাপনাকে সহজ করেছে, কায়িক শ্রম কমিয়েছে।

- বৃদ্ধির জন্য নমনীয়তা. ডিবার্কারের স্কেলেবিলিটি নিশ্চিত করে যে এটি ব্যবসার বৃদ্ধির সাথে সাথে ভবিষ্যতের উৎপাদন চাহিদা পূরণ করতে পারে।

- নির্ভরযোগ্য কর্মক্ষমতা। কাঠের ডিবার্কারের শক্ত নকশা শুষ্ক এবং ভেজা কাঠ উভয় প্রক্রিয়াকরণের সময়ও সুসংগত অপারেশন নিশ্চিত করে।

উপসংহার

এই প্রকল্পটি আমাদের বৈশ্বিক ক্লায়েন্টদের জন্য বিশেষভাবে প্রস্তুতকৃত সমাধান প্রদান করার প্রতিশ্রুতি তুলে ধরে। জাম্বিয়ায় একটি উচ্চমানের কাঠের ডিবার্কার সরবরাহ করে, আমরা গ্রাহককে একটি প্রতিযোগিতামূলক কাঠ প্রক্রিয়াকরণ অপারেশন প্রতিষ্ঠা করতে সাহায্য করেছি।

আমরা প্রতিটি প্রকল্পে সাফল্য নিশ্চিত করে দক্ষ এবং উদ্ভাবনী সরঞ্জাম সমাধান সহ বিশ্বব্যাপী ব্যবসার ক্ষমতায়নের জন্য নিবেদিত রয়েছি।