팔레트 블록 생산 분야에서 중요한 고려 사항은 구멍을 포함할지 또는 비다공성 구조를 유지할지를 결정하는 것입니다. 이 결정은 공기 투과성, 습기 저항, 못 박기 용이성 등과 같은 요소에 직접적인 영향을 미치므로 매우 중요합니다.

이 기사에서는 구멍이 있는 팔레트 블록과 구멍이 없는 팔레트 블록의 차이점을 살펴보고 각 변형과 관련된 장점과 고려 사항을 조명합니다.

구멍이 있는 팔레트 블록:

장점:

- 공기 투과성: 팔레트 블록의 중앙 세로 구멍을 통해 메탄올과 수증기가 배출됩니다. 이 기능은 목재 큐브의 공기 투과성을 향상시켜 습기로 인한 팽창을 방지하고 결과적으로 수명을 연장시킵니다.

- 내습성: 중앙 구멍을 통해 습기를 방출하는 구멍이 있는 팔레트 블록의 능력으로 인해 습기로 인한 팽창이 덜 발생하므로 다양한 환경 조건에서 적용하기에 적합합니다.

고려사항:

- 못박기 과제: 중앙 구멍은 여러 가지 이점을 제공하지만 못 박는 과정에서는 문제가 됩니다. 실수로 중앙 구멍에 못을 박는 일이 없도록 주의해야 합니다. 이로 인해 팔레트 블록의 구조적 무결성이 손상될 수 있습니다.

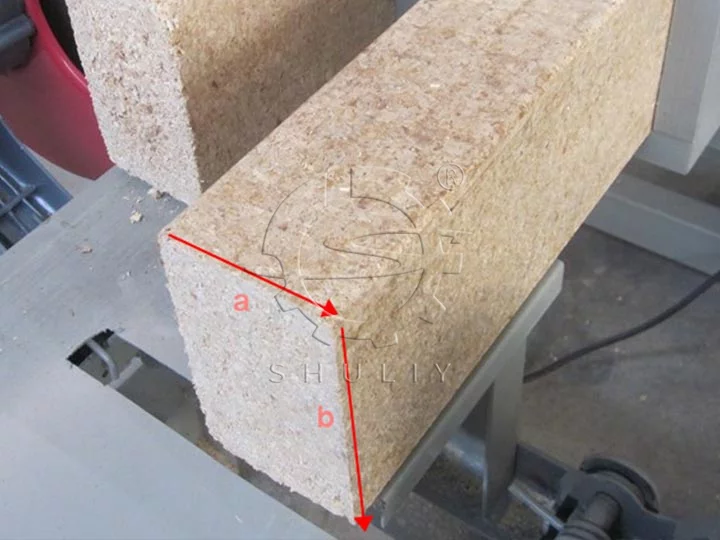

구멍이 없는 팔레트 블록:

장점:

- 편리한 못박기: 구멍이 없는 팔레트 블록은 완전히 조밀하여 중앙 구멍이 없습니다. 이러한 특성으로 인해 못질 작업이 더욱 편리해지며 조립 과정에서 중앙 빈 공간을 탐색할 필요가 없습니다.

고려사항:

- 감소된 공기 투과성: 구멍이 없는 팔레트 블록에 구멍이 없으면 구멍이 있는 팔레트 블록에 비해 공기 투과성이 제한될 수 있습니다. 이러한 측면은 팔레트 구조 내의 공기 순환이 중요한 고려 사항인 응용 분야에서 매우 중요합니다.

- 수분 민감도: 구멍이 없는 팔레트 블록은 구멍이 있는 팔레트 블록에 비해 습기 관련 문제에 더 취약할 수 있습니다. 중앙 구멍이 없으면 메탄올과 수증기의 방출이 제한되기 때문입니다.

사용자 결정 밀도:

구멍이 있는 팔레트 블록과 구멍이 없는 팔레트 블록 간의 선택은 주로 최종 사용자의 밀도 요구 사항에 따라 결정됩니다. 목재 밀도가 높을수록 일반적으로 하중 지지력이 향상되므로 특정 적용 분야 요구 사항에 맞게 팔레트 블록 구조를 선택하는 것이 필수적입니다.

결론:

결론적으로 구멍이 있는 팔레트 블록을 사용할지 구멍이 없는 팔레트 블록을 사용할지 결정하려면 공기 투과성, 습기에 대한 저항성, 못박기 용이성 등의 요소를 신중하게 고려해야 합니다. 각 변형과 관련된 고유한 장점과 고려 사항을 이해하면 사용자는 특정 밀도 요구 사항 및 응용 분야 요구 사항에 따라 정보를 바탕으로 선택할 수 있습니다.

궁극적으로 구멍이 뚫려 있거나 완전히 조밀한 팔레트 블록은 물류 및 운송 산업에서 중요한 역할을 하며 해당 디자인은 의도한 응용 분야의 요구 사항에 부합해야 합니다.