คำอธิบายโดยย่อของเครื่องทำผงไม้

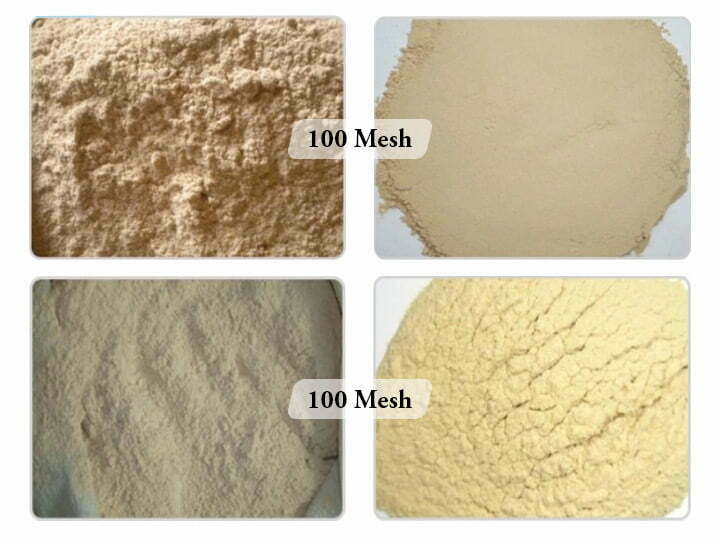

เครื่องทำผงไม้เชิงพาณิชย์นี้เรียกอีกอย่างว่าเครื่องผงไม้แนวนอน ส่วนใหญ่จะใช้สำหรับบดเศษไม้และขี้เลื่อยเพิ่มเติมเพื่อสร้างอนุภาคแป้งไม้ที่มีความละเอียด 30-300 ตาข่าย และแป้งไม้สามารถนำไปใช้ทำธูปและกระดาษแข็งได้หลากหลาย

พารามิเตอร์ทางเทคนิคของโรงโม่แป้งไม้ไฟฟ้า

| แบบอย่าง | SL-450 | SL-500 | SL-600 | SL-750 | SL-800 |

| ความชื้นของวัสดุ | ต่ำกว่า 2% | ต่ำกว่า 2% | ต่ำกว่า 2% | ต่ำกว่า 2% | ต่ำกว่า 2% |

| ความละเอียดในการบด (ตาข่าย) | 40-200 | 40-300 | 40-300 | 40-300 | 40-300 |

| ความเร็วในการหมุนของมอเตอร์ (รอบ / นาที) | 2900 | 2900 | 2900 | 2900 | 2900 |

| กำลังไฟ (กิโลวัตต์) | 18.5/2 | 22/2 | 30/2 | 37/2 | 45/2 |

| กำลังพัดลม (กิโลวัตต์) | 5.5/2 | 5.5/2 | 7.5/2 | 7.5/2 | 7.5/2 |

| น้ำหนัก (กก.) | 1500 | 2100 | 2500 | 3100 | 3300 |

| ความจุ(กก./ชม.) | 30-300 | 40-500 | 60-800 | 100-500 | 120-2000 |

การใช้งานเครื่องผงไม้แนวนอน

ไม้ไผ่, เปลือก, สมุนไพรจีน, เปลือกไม้, ใบไม้, รำข้าวสาลี, เผือก, งา, แกลบ, ซังข้าวโพด, ก้านส้ม, แป้ง, อาหาร, เปลือกกุ้ง, ปลาป่น, สาหร่ายทะเล, ผักอบแห้ง, ฮอว์ธอร์น, ขิงแห้ง, กระเทียมสไลซ์อบแห้ง, เครื่องปรุงรส, พุทรา, กระดาษ, แผงวงจร, พลาสติก, วัตถุดิบเคมี, ไมกา, กราไฟต์, เพอร์ไลต์, กากตะกอน, ฟูร์ฟูรัล, ถ่าน, ถ่านกัมมันต์, เซลลูโลส, กากมันฝรั่ง, ชา, กากถั่วเหลือง, ฝ้าย, รากพืช, ลำต้น, ใบ, ดอกไม้และผลไม้แห้ง, เห็ดกินได้แห้งต่างๆ เป็นต้น สามารถบดได้ด้วยเครื่องบดแป้งไม้นี้

เครื่องทำผงไม้นี้มีความหลากหลายมาก เหมาะสำหรับการบดละเอียดเป็นพิเศษของวัสดุที่ไม่ใช่แร่ทั่วไป วัสดุที่ไม่ติดไฟ และวัตถุระเบิดที่มีความแข็ง Mohs ต่ำกว่าเกรด 6 เครื่องบดมักใช้ในอุตสาหกรรมเคมี วัสดุก่อสร้าง ยา การดูแลสุขภาพ การเพาะพันธุ์ อาหาร ยาจุดกันยุง และอุตสาหกรรมอื่นๆ

เครื่องทำผงแป้งไม้ทำงานอย่างไร?

เครื่องผงไม้เนื้อละเอียดพิเศษเป็นอุปกรณ์บดแบบค้อน ถังบดได้รับการออกแบบด้วยค้อนที่จัดเรียงเท่าๆ กันหลายกลุ่มและตะแกรงที่ถอดออกได้ และความเร็วสูง ซึ่งสามารถกระแทกวัสดุได้อย่างรวดเร็วเพื่อให้บรรลุวัตถุประสงค์ของการบด ในกระบวนการผลิตแป้งไม้จริง เครื่องทำแป้งไม้มักจะต้องใช้พัดลม (1-2 กลุ่มขึ้นไป) เครื่องวิเคราะห์ความละเอียด และเครื่องเก็บฝุ่นแบบถุงเพื่อรวบรวมอนุภาคแป้งไม้เนื้อดีเพื่อป้องกันมลพิษจากฝุ่น

เมื่อเครื่องโม่แป้งไม้ทำงาน มอเตอร์จะขับเคลื่อนโรเตอร์ของเครื่องบดให้ทำงานด้วยความเร็วสูง ส่งผลให้เครื่องสร้างกระแสลมความเร็วสูง และสร้างแรงกระแทกที่มีความแข็งแรงสูง แรงอัด แรงตัด และแรงเสียดทานบน วัสดุที่จะบด วัสดุจะถูกเร่งความเร็วในการไหลของอากาศ และถูกกระแทก ตัด และถูซ้ำๆ และต้องเผชิญกับเอฟเฟกต์การบด 3 แบบพร้อมกัน และสุดท้ายก็บรรลุฟังก์ชันการบดที่เป็นเอกลักษณ์

ต่อจากนั้น วัสดุที่ถูกบดจะเข้าสู่เครื่องวิเคราะห์เพื่อวิเคราะห์ด้วยการไหลของอากาศ เนื่องจากแรงเหวี่ยงของโรเตอร์ของเครื่องวิเคราะห์และแรงสู่ศูนย์กลางของการไหลของอากาศ เมื่อแรงเหวี่ยงมากกว่าแรงสู่ศูนย์กลาง อนุภาคผงไม้ที่ละเอียดกว่าจะเข้าสู่ตัวเก็บผงพร้อมกับการไหลของอากาศที่สะสม ผงไม้ที่มีอนุภาคขนาดใหญ่จะเข้าสู่ห้องบดและบดต่อไปจนกว่าจะถึงความละเอียดที่ต้องการ

คุณสมบัติหลักของเครื่องบดโม่แป้งไม้

1. ความละเอียดของผลิตภัณฑ์ที่ประมวลผลโดยเครื่องแป้งไม้แนวนอนนี้สามารถปรับได้โดยพลการระหว่าง 30-300 ตาข่าย และผลลัพธ์และความละเอียดจะแตกต่างกันไปตามสัดส่วนของวัสดุที่จะแปรรูป มอเตอร์หลักของโรงโม่แป้งไม้อาจมีขนาดใหญ่หรือเล็ก ขึ้นอยู่กับความละเอียดและผลผลิตของวัสดุ

2. เครื่องทำผงไม้นี้มีตัวควบคุมปริมาณลม ซึ่งสามารถปรับปริมาณลมของพัดลมได้ เมื่อปริมาณอากาศมีมาก ความละเอียดของผงไม้จะต่ำ และเมื่อปริมาณอากาศน้อย ความละเอียดของผงไม้ก็จะสูง สามารถผลิตเครื่องได้อย่างต่อเนื่องโดยการปรับเครื่องให้ได้ความละเอียดที่ต้องการ