공장에서 가금류 사료 펠렛을 대량 생산하려면 원료 분쇄 및 건조, 사료 펠렛화 및 완제품 냉각을 포함한 완전한 가공 절차가 필요합니다.

가금류에게 펠렛 사료를 공급할 때의 장점

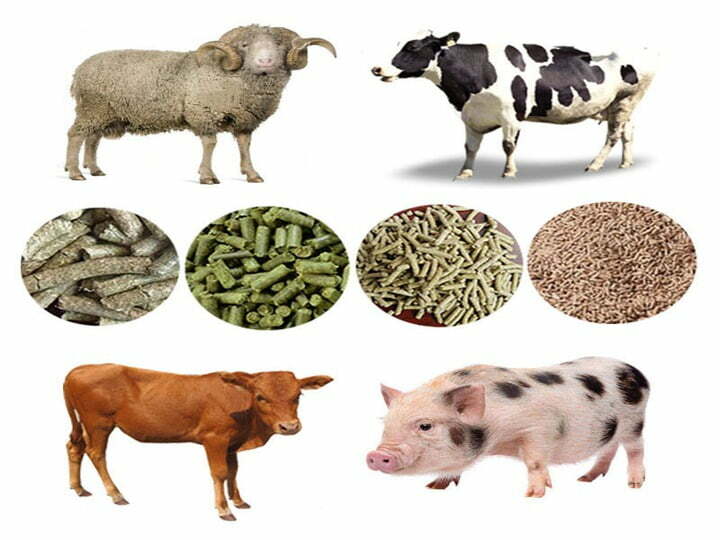

펠릿 사료 기계는 많은 장점으로 사료 가공 산업 및 사육 산업에서 널리 사용됩니다. 가금류 사료 펠릿 제조 기계 로 생산된 펠릿 사료는 밀도가 높고 수분 함량이 낮아 운송 및 보관이 편리합니다.

동시에, 펠렛사료는 이미 사료의 다양한 영양소를 혼합하고 각 사료 펠릿에는 사육 동물이 필요로 하는 모든 영양소가 포함되어 있기 때문에 가금류나 가축과 관련된 전통적인 농업 방법도 피합니다. 다양한 음식을 먹이는 번거로운 절차입니다. 동시에, 이 영양가 있는 펠렛 사료는 입맛이 까다로운 일부 사람들이 종합적인 영양을 섭취할 수 있게 해줍니다.

가금류 사료 펠렛 제조 공정 흐름

원료 분쇄

재료 분쇄는 펠릿화하기 전에 가금류 사료 펠렛에 없어서는 안될 작업입니다. 피드밀에서 분쇄된 재료만 펠릿 기계로 가공할 수 있습니다. 일반적으로 재료의 분쇄 크기는 압축된 공급 입자의 직경과 관련이 있습니다.

일반적으로 생산될 입자의 직경이 얼마나 되는지에 따라 원료의 입자 크기도 이 숫자가 됩니다. 예를 들어, 사료 입자 직경 요구 사항이 5mm인 경우 재료는 5mm 이하로 분쇄해야 합니다. 가금류 사료 펠릿 기계 제조업체는 사용자가 6mm 이하로 재료를 분쇄할 수 있으며 이는 모든 유형의 가금류 사료 펠릿 생산에 적합하다고 권장합니다.

원료 수분은 약 13%로 유지되어야 합니다.

많은 사람들은 소와 양 짚 사료 펠렛 기계를 사용하기 전에 원료의 수분 함량을 조절하는 방법을 모릅니다. 가금류 펠릿 사료 기계는 안팎으로 건조되어 있습니다. 이는 펠릿 기계가 재료의 수분에 대해 엄격한 요구 사항을 가지고 있음을 의미합니다. 사용자는 재료 수분을 약 13%로 유지하는 것이 좋습니다. 과립화하기 전에 재료가 상대적으로 젖어 있는 경우 먼저 건조해야 합니다.

과립화할 때 균일한 속도로 공급해야 합니다.

가금류 사료 펠릿 기계가 균일한 속도로 공급되는지 여부는 펠릿 기계가 정상적으로 작동할 수 있는지 여부와 관련이 있습니다. 공급 속도가 너무 빠르면 사료 펠릿 기계의 배출구에서 재료가 넘칠 수 있습니다. 공급 속도가 너무 느리면 펠릿 기계가 공회전하기 쉽습니다. 따라서 공급 속도를 일정하게 유지하면 가금류 사료 펠릿 기계의 정상적인 작동을 보장하고 펠릿 기계의 작업 효율성을 향상시킬 수 있습니다.