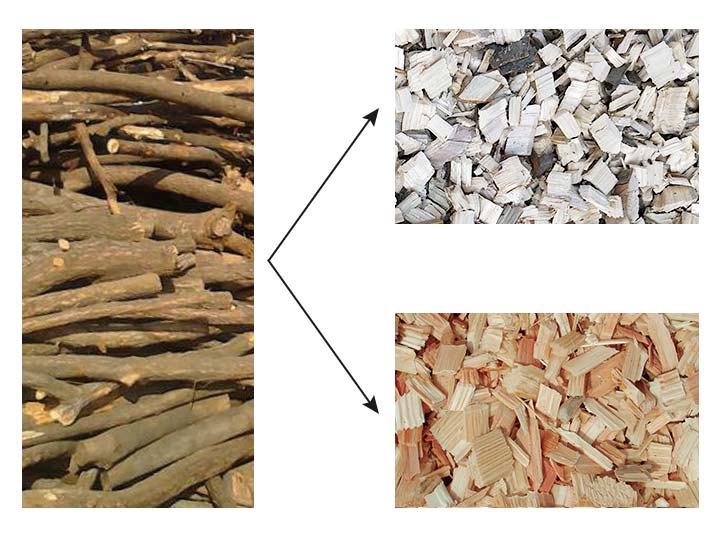

O picador de madeira com disco pode transformar com eficiência toras, galhos e resíduos de madeira em lascas de madeira de tamanho uniforme. Pode efetivamente reduzir o volume de subprodutos florestais, restos de poda de árvores e resíduos de produção de madeira.

Alimentado por motores a gasolina e diesel, este picador oferece uma solução sustentável com diversas aplicações, incluindo cobertura morta, compostagem, produção de combustível e fornecimento de matérias-primas para diversas indústrias.

Com capacidade que varia de 500 a 8.000 kg/h, o Picador de Madeira a Disco é versátil e capaz de atender às demandas de diversos ambientes de produção.

Características estruturais da máquina picadora de madeira para venda

A Shuliy Machinery projeta e fabrica os equipamentos de estilhaçamento de madeira mais avançados do setor, exportando essas máquinas de alta qualidade para muitos países em todo o mundo.

Nosso picador de madeira de disco possui uma estrutura robusta e eficiente semelhante às máquinas de barbear madeira, mas com um design e formato de disco de corte distintos.

Dependendo dos diferentes ambientes de aplicação, os picadores de madeira de disco são classificados em dois tipos principais:

- Picadores de madeira com descarga superior. Projetado para descarregar cavacos de madeira pela parte superior da máquina, ideal para requisitos operacionais específicos.

- Picadores de madeira com descarga inferior. Construído para liberar lascas de madeira do fundo, adequado para diferentes ambientes de trabalho.

Os principais componentes do nosso picador de madeira de disco incluem:

- Quadro

- Acoplamento

- Motor

- Cabeça de corte

- Polia

Cada um desses elementos é cuidadosamente elaborado para garantir desempenho e durabilidade ideais.

Picador de madeira com descarga superior

Os picadores de madeira de descarga superior à venda são geralmente menores e podem ser fixados em um local específico ou montados em uma estrutura com rodas para fácil mobilidade.

Este projeto é particularmente adequado para operações móveis, permitindo que os cavacos de madeira processados sejam depositados diretamente em equipamentos de armazenamento, como a carroceria de um caminhão.

Picador de madeira com descarga inferior

A máquina picadora de madeira de descarga inferior é normalmente maior e projetada para produção contínua em instalações de processamento de madeira. Esta máquina está disponível em configurações fixas e móveis.

Durante a operação, um dispositivo de transporte automático é normalmente instalado abaixo da porta de descarga para transportar automaticamente os cavacos de madeira processados para o compartimento de armazenamento.

Vídeo de funcionamento da máquina picadora de madeira

Dados técnicos de picadores elétricos de madeira

| Modelo | Capacidade | Tamanho de entrada | Tamanho da saída | Energia elétrica |

| WD-420 | 500kg/hora | 150*150MM | 2-5cm | 11 kW |

| WD-600 | 1500kg/hora | 180*150MM | 2-5cm | 18,5 kW |

| WD-800 | 3000kg/h | 200*200MM | 2-5cm | 30 kW |

| WD-950 | 4000kg/h | 230*250MM | 2-5cm | 37 kW |

| WD-1200 | 5000kg/hora | 330*300MM | 2-5cm | 55 kW |

| WD-1400 | 7000-8000kg/h | 400*400MM | 2-5cm | 90 kW |

Aplicações de cavacos de madeira

Os cavacos de madeira produzidos por nosso picador de madeira atendem a uma infinidade de propósitos, demonstrando sua versatilidade e valor em vários setores.

- Geração de energia. Nossos cavacos de madeira são ideais para combustível de biomassa em usinas de energia. Seu tamanho uniforme e combustão eficiente fazem deles uma fonte de energia sustentável e renovável.

- Vendas de madeira premium. Lascas de madeira uniformes e de alta qualidade são perfeitas para materiais de madeira premium. Eles são procurados para aplicações em paisagismo, jardinagem e artesanato em madeira.

- Produção de papel. Nossos picadores de madeira produzem cavacos de madeira padrão da indústria, servindo como matéria-prima essencial na indústria de papel e celulose para diversos produtos de papel.

Vantagens dos picadores de madeira de disco Shuliy

- Converta com eficiência toras e galhos grandes em lascas de madeira uniformes.

- Use um disco de corte preciso para obter resultados consistentes.

- Disponível com configurações de descarga superior ou inferior para atender aplicações específicas.

- Adequado tanto para instalações fixas como para operações móveis, oferecendo grande versatilidade.

- Pode ser equipado com sistema de transporte automático para agilizar o transporte de cavacos de madeira processada.

- Ideal para manejo florestal e indústrias de processamento de madeira.

Máquina picadora de madeira Shuliy, embalagem e exportação

O picador de disco possui uma estrutura compacta e uma eficiência de trabalho muito alta, o que é muito popular nos mercados internacionais.

Atualmente, exportamos um grande número de picadores de madeira para países do Sudeste Asiático e países africanos, como Indonésia, Vietname, Filipinas, Quénia, Uganda, Etiópia, Ruanda, África do Sul, etc.

Também fabricamos máquinas de lascas de madeira, trituradores de madeira e outros equipamentos de processamento de madeira, se estiver interessado, consulte-nos a qualquer momento.

Qual é o preço do picador de madeira de disco?

O preço de um picador de madeira de disco varia de acordo com vários fatores, incluindo tamanho, capacidade e características específicas. Geralmente, os custos são influenciados pela configuração da máquina, como se é um modelo fixo ou móvel, e pelas opções adicionais ou personalizações necessárias.

Para um orçamento preciso e adaptado às suas necessidades, entre em contato conosco diretamente para discutir seus requisitos específicos e condições operacionais.

Perguntas frequentes sobre máquinas para fazer lascas de madeira

Que tipos de madeira o picador de madeira pode manusear?

Nosso picador de madeira pode processar uma variedade de tipos de madeira, incluindo madeira dura, madeira macia, galhos e até mesmo alguns tipos de troncos de árvores.

Porém, para um ótimo desempenho, é essencial garantir que a madeira esteja dentro do tamanho recomendado e nas condições por nós especificadas.

Com que frequência o picador de madeira requer manutenção?

A manutenção regular é crucial para garantir a longevidade e a eficiência do picador de madeira.

Normalmente, as tarefas de manutenção incluem a verificação e afiação das lâminas, a lubrificação de peças móveis e a inspeção de desgaste ou danos.

Recomenda-se seguir o cronograma de manutenção fornecido no manual do usuário.

O picador de madeira pode ser usado em climas frios?

Sim, o picador de madeira pode operar em climas frios, mas é importante seguir os procedimentos adequados de preparação para o inverno.

Isso pode incluir o uso de lubrificantes adequados, garantindo que a máquina esteja devidamente aquecida antes do uso e mantendo a máquina livre de gelo e neve.

Qual é a vida útil esperada do picador de madeira?

A vida útil do picador de madeira depende de fatores como frequência de uso, práticas de manutenção e condições operacionais.

Com os devidos cuidados e manutenção regular, nosso picador de madeira foi projetado para fornecer muitos anos de serviço confiável.

Contate-nos

O Desintegrador de Madeira se destaca com sua tecnologia de corte avançada e construção durável, projetado para lidar com uma ampla gama de tamanhos e tipos de madeira. Sua operação de alta eficiência não apenas maximiza a produção, mas também minimiza as necessidades de manutenção.

Explore os benefícios do nosso picador de madeira a disco e descubra como ele pode aprimorar suas capacidades de processamento de madeira entrando em contato conosco hoje mesmo.