In early 2025, our SL-S500 wood peeler for sale was successfully delivered to Vietnam, supporting a local wood processing enterprise in improving log peeling efficiency and finished wood quality.

As a reliable and versatile wood peeler for sale, this machine has become the ideal choice for upgrading their production line due to its high efficiency, low waste, and easy operation.

Project background

Vietnam is rich in forest resources, and its wood processing industry is rapidly growing. A local enterprise was looking for a high-performance wood peeler for sale to increase peeling efficiency and improve the quality of processed timber.

Their main requirement was to handle medium-diameter logs with standard lengths, achieving smooth peeling surfaces with minimal waste, while ensuring machine stability. After detailed evaluation, they finally chose the SL-S500 wood peeler to upgrade their production line.

Wood peeler for sale selection and features

The customer selected the SL-S500 wood peeler, a robust and stable machine suitable for a wide range of log peeling applications. Its main features include:

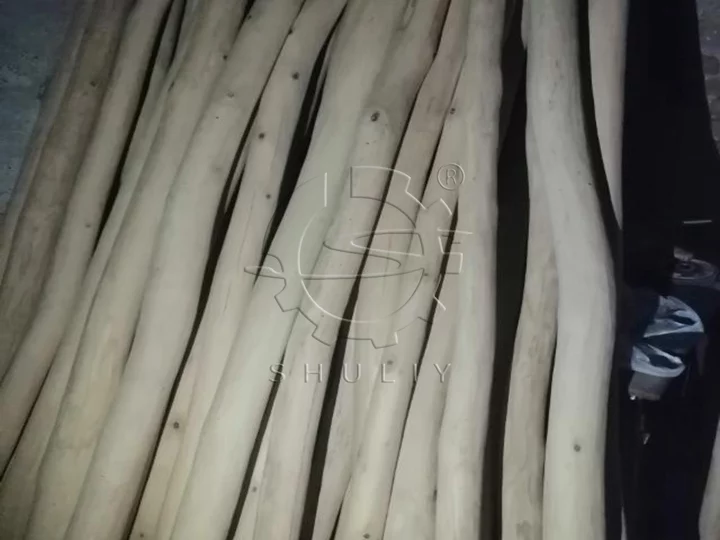

- High peeling efficiency: The SL-S500 can quickly strip bark, leaving a smooth wood surface that is ideal for subsequent processes such as planing, veneer cutting, or plywood production.

- Wide adaptability: It can handle both hardwood and softwood, covering a wide range of log diameters and lengths, making it well-suited to Vietnam’s diverse forestry resources.

- Stable performance with low waste: Its durable structure minimizes the need for frequent part replacement. Wood waste during peeling is significantly reduced, while byproducts like bark are easy to recycle.

Implementation process

- Requirement communication & order confirmation

The customer discussed log types, dimensions, peeling precision, and production efficiency with us before confirming the purchase of the SL-S500 as their chosen wood peeler for sale. - Manufacturing & delivery

After production and testing at the factory, the machine was carefully packed and shipped by sea to Vietnam. Special attention was given to moisture-proofing and vibration protection during transportation. - Installation, commissioning & training

Upon arrival at the customer’s factory, engineers guided the installation, aligned feeding and output systems, and provided operator and maintenance staff training to ensure smooth operation according to design parameters. - Trial run & acceptance

The machine entered the trial run phase, where peeling speed, surface smoothness, and output capacity were tested. The customer confirmed that the machine met all requirements and officially put it into mass production.

Customer feedback

The customer expressed high satisfaction with the SL-S500, particularly appreciating its peeling quality, efficiency, stability, and ease of maintenance. They emphasized that this wood peeler for sale not only met their immediate needs but also provided a strong foundation for future expansion.