Cattle feed pellets making machine is equipment for processing various animal feed pellets. The user should master the correct operation manual in order to produce more efficiently. Our Shuliy factory has compiled the latest installation and operation manuals and explanation videos of the feed pellet machine, hoping to help the most poultry feed pellets processors.

Operation guidance for using cattle feed pellets making machine

Step 1 Connect the receiving tray with the pellet machine

Connecting the discharging tray to the discharging port of the feed pellet machine can make the discharging of the machine smoother and facilitate the collection and storage of finished products. The method of installing the tray is very simple, just loosen the screws on both sides of the discharge port, then fix both sides of the tray and tighten the screws.

Step 2 Add gear oil before starting the machine

gear oil injection hole

gear oil

The reason why we need to add more gear oil to the gearbox of the cattle feed pellets making machine is to reduce the friction between the gears of the machine and prolong the service life of the machine. It should be noted that different types of feed pellet mills have different gear oil injection volumes. Generally speaking, the SL-125 needs to be injected about 3L, while the SL-210 needs to be injected about 10L.

Step 3 Connect the motor wires of the feed pellet machine

Before using the machine, the user must follow the instructions in the manual to correctly wire the motor. Otherwise, the motor will be damaged and the machine cannot be used. Our cattle feed pellet machine has specific wiring instructions, users only need to follow the instructions in the manual for wiring.

After the motor wiring is completed, we need to start the machine to observe the direction of rotation of the grinding disc. If the grinding disc rotates counterclockwise, it means that the wiring of the motor is correct. If it’s in the opposite direction, it means the wire is connected reversely and needs to be re-wired.

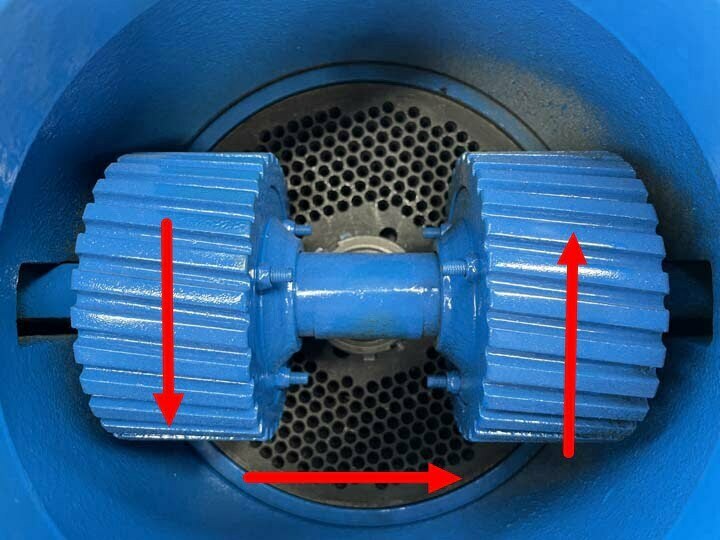

Step 4 Check if the rollers are loose

Before using the poultry feed pellet machine, check whether the roller of the machine is loose. If the rollers are loose, we need to tighten the screws on both sides of the roller. After the tightening is completed, a test is to be carried out until the rollers are not loose.

Step 5 Add materials to make pellets

Mix 40% sawdust, 40% sand, and 20% engine oil. Then put the mixed material into the feed pellet machined silo. At first, slowly put in a small number of materials, and observe the final product. If the machine can work normally, you can put the materials into silo more, then grind the materials for about 30-60 minutes.