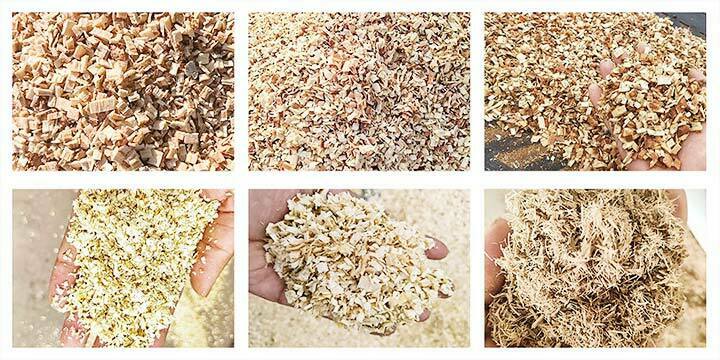

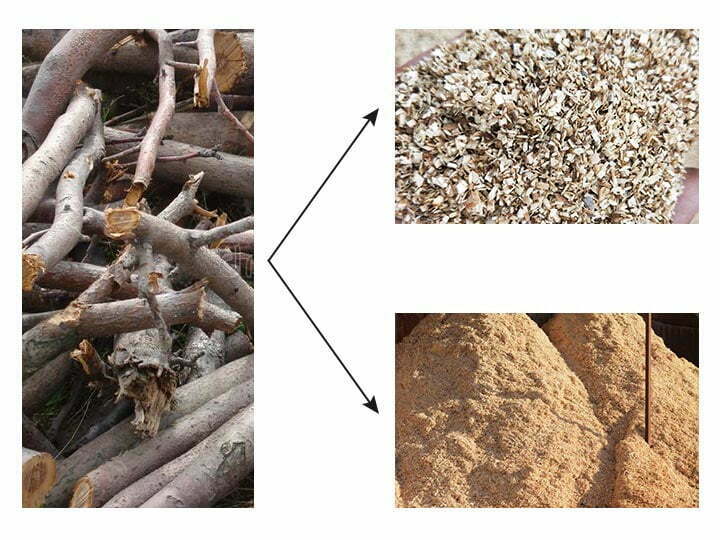

Wood crusher shredders, also known as sawdust making machines, can convert various types of hardwoods, logs, branches, straws, and agricultural or forestry waste into uniformly fine sawdust. The wood crushers can handle a broad range of materials, from logs to branches, making them suitable for diverse applications.

At Shuliy factory, we offer both electric and diesel-driven versions of the wood shredder. While the appearance, structure, and functionality of both types are identical, they differ only in their power source. The wood shredder machines feature an outlet size ranging from 0.3 to 1.2 cm and can achieve a capacity of 300-5000 kg/h, catering to various processing needs.

Electric wood crusher for sale

The electric wood crusher is driven by a motor, with power levels varying depending on the model. Larger models feature higher motor power, resulting in greater output and efficiency.

These crushers are usually installed in fixed locations, such as factories, where they deliver stable and continuous wood processing performance.

Technical parameters of electric wood crushing machine

| MODEL | CAPACITY | INPUT SIZE | OUTLET SIZE | POWER |

| SL-420 | 500KG/H | 13cm | 0.3-1.2cm | 7.5-11kw |

| SL-500 | 800KG/H | 15cm | 0.3-1.2cm | 18.5kw |

| SL-600 | 1000KG/H | 18cm | 0.3-1.2cm | 30kw |

| SL-700 | 1500-2000KG/H | 20cm | 0.3-1.2cm | 37kw |

| SL-800 | 2500KG/H | 20cm | 0.3-1.2cm | 37-55kw |

| SL-900 | 3000KG/H | 28cm | 0.3-1.2cm | 55kw |

| SL-1000 | 3500KG/H | 28cm | 0.3-1.2cm | 75+7.5kw |

| SL-1200 | 4000KG/H | 36cm | 0.3-1.2cm | 90kw |

| SL-1500 | 4500KG/H | 44cm | 0.3-1.2cm | 110kw |

| SL-1800 | 5000KG/H | 50cm | 0.3-1.2cm | 132kw |

Diesel-driven wood shredder machine

The diesel-driven wood shredder machine uses a diesel engine for power, making it mobile and easy to operate in different locations. Unlike stationary electric models, it doesn’t rely on fixed power sources.

Thanks to its flexibility, this machine is ideal for use in various environments like forests, mountains, farms, and open fields, providing efficient wood processing wherever it’s needed.

Technical parameters of the diesel-driven wood shredder

| Model | Capacity | Power | Feeding size | Outlet size |

| SL-420 | 300-400kg/h | 11kW motor or 15hp diesel engine | 10cm | 0.3-0.8cm |

| SL-500 | 500-600kg/h | 18.5 kW motor or 30hp diesel engine | 15cm | 0.3-0.8cm |

| SL-600 | 800-1000kg/h | 30 kW motor or 60hp diesel engine | 17cm | 0.3-0.8cm |

| SL-700 | 1200-1500kg/h | 37 kW motor or 60hp diesel engine | 20cm | 0.3-0.8cm |

| SL-900 | 2000-2500kg/h | 55 kW motor or 80hp diesel engine | 22cm | 0.3-0.8cm |

| SL-1000 | 3000-3500kg/h | 75kW motor or 110hp diesel engine | 26cm | 0.3-0.8cm |

| SL-1200 | 3500-4000kg/h | 90 kW or 130hp diesel engine | 28-30cm | 0.3-0.8cm |

Wood shredder main structure

The commercial wood crushing machine is a newly designed piece of equipment for efficient wood crushing and recycling. Based on extensive after-sales tracking and customer feedback, we have optimized and upgraded these machines for better performance.

Main components of the hammer mill

- Frame. Provides the structural support for the machine.

- Base. Ensures stability during operation.

- Motor. Powers the machine, with variations in models for different needs.

- Pulley. Facilitates the transfer of power.

- Shredding chamber

- Knife disc. Cuts the material.

- Hammers. Shreds the material.

- Screen. Controls the size of the output.

To cater to diverse customer needs, our wood shredders are available in various types:

- Diesel-driven wood crushing machines

- Electric wood shredders

- Stationary wood crushers

- Mobile wood shredder hammer mills

These options provide flexibility and adaptability for different operational environments.

Key advantages

- Compact structure. Designed for space efficiency.

- Simple and smooth operation. Ensures ease of use.

- High production efficiency. Delivers superior processing capability.

How does a wood crusher shredder work?

- Initial cutting

- Wood and branches are fed into the machine.

- Internal blades quickly chop the material into smaller wood chips.

- Crushing

- The rotor drives the chips into the crushing chamber.

- Hammers continuously pound the chips into finer debris.

- Screening and extraction

- Fine particles pass through mesh screen holes.

- These are extracted by a fan and collected in a dust removal unit.

- Re-crushing

- Larger chips that can’t pass through the screen stay in the chamber.

- They are crushed repeatedly until fine enough to exit through the mesh.

Applications of the wood crushers

The wood chips produced by these machines serve as valuable raw materials for multiple purposes, contributing to sustainable practices and efficient resource utilization.

Key applications

- Wood processing plants

- Used to convert raw wood materials into chips for further processing.

- Supports the production of wood-based products, such as paper and fiberboard.

- Charcoal processing plants

- Wood chips are used as a precursor for producing high-quality charcoal.

- Ensures efficient use of wood waste in charcoal production.

- Wood board manufacturing

- Provides consistent wood chips for the production of particleboard and other wood panels.

- Enhances the quality and uniformity of wood board products.

- Biomass pellet production

- Converts wood chips into biomass pellets for use as a renewable energy source.

- Contributes to the production of eco-friendly fuel for heating and power generation.

These versatile applications highlight the importance of wood crushers in both industrial and agricultural settings, where they contribute to resource conservation and energy efficiency.

Advantages of wood hammer mills

- Durable construction. We use thicker steel plates to enhance wear resistance and extend the machine’s service life, prioritizing quality over production costs.

- High-quality motors. Our wood shredders are equipped with brand-name motors, ensuring smooth operation and reducing the likelihood of breakdowns.

- Reliable after-sales support. We provide ongoing after-sales services, including installation guidance and usage support, to ensure customers get the most out of their wood shredders.

Working video of the wood crusher for sale

Wood crusher shredder machine shipment to foreign countries

Over the past 10 years, Shuliy factory has successfully exported various types of wood shredders and other wood processing equipment to more than 50 countries and regions.

Our machines have been well-received in numerous international markets, demonstrating their reliability and performance.

Countries and regions we serve

- Asia: Thailand, Vietnam, Malaysia, Singapore, Pakistan, UAE, Saudi Arabia, Yemen, Russia

- Oceania: New Zealand

- North America: Canada, United States

- Europe: United Kingdom, Serbia

- South America: Venezuela, Chile, Brazil

- Africa: Nigeria, South Africa, Somalia, Uganda, Egypt

In addition to wood shredders, we also offer a range of other equipment, including wood shaving machines and wood chipper machines. For more information, feel free to consult us at any time.

Conclusion

Our wood crusher is designed for efficient, multi-stage processing—from initial cutting to fine crushing and dust-free extraction—ensuring high output and uniform particle size.

If you’re looking for a powerful solution to improve your wood processing efficiency, feel free to contact us for more details and a competitive quote!