The Sawdust Wood Pallet Block Machine can compress sawdust, wood chips, and other wood waste into high-density pallet blocks through high-temperature heating and high-pressure extrusion. The machine typically consists of an automatic feeding system, heating unit, extrusion mold, and electronic control system, enabling loose raw materials to be directly formed into uniform, smooth, and strong pallet support blocks.

These blocks are widely used in wooden pallets and logistics packaging, and the finished products do not require fumigation, meeting export standards. In terms of basic parameters, the machine has a daily output of approximately 2–6 cubic meters, with customizable block dimensions generally ranging from 75–145 mm, and a total power of about 15–18 kW, providing stable operation and controllable energy consumption.

By using the Sawdust Wood Pallet Block Machine, companies can efficiently convert wood waste into high-value products, reduce pallet production costs, and improve resource utilization and production efficiency.

What is the sawdust wood pallet block?

A sawdust wood pallet block is a solid support block used in wooden pallets, made by compressing sawdust, wood chips, and other wood residues under high temperature and high pressure. Through this process, loose wood waste is formed into dense, uniform blocks with high strength and durability. Sawdust wood pallet blocks are commonly used as pallet feet or spacers in logistics and packaging industries.

Compared with traditional solid wood blocks, they offer stable quality, precise dimensions, and do not require fumigation, making them suitable for export pallets while also improving wood waste utilization and reducing material costs.

Raw materials for making sawdust wooden blocks

A diverse array of waste biomass materials serves as the raw resources for manufacturing sawdust wooden blocks.

These materials encompass branches, sawdust, wood processing remnants, wood shavings, rice husks, straw, pine, hardwood, logs, among others.

Prior to the production of sawdust pallet blocks, these raw materials must undergo processing through a wood shredder to be transformed into sawdust.

Wood pallet block machine for sale

If you’re in the market for a wood pallet block machine, you’ll find our equipment to be highly efficient and versatile. As the primary device for processing wooden cubes and tiles, it comes equipped with two reverse feed inlets designed for sawdust storage. Additionally, the machine features four outlets dedicated to the extrusion of pallet blocks.

Our sawdust pallet block making machine incorporates electric heating functionality. During the wood block extrusion process, the heating plate remains continuously heated, enabling the lignin in the sawdust to melt and bind together.

This results in pallet blocks that are more solid and have a higher density. Furthermore, the export mold of the machine can be easily replaced with molds of various sizes, allowing you to produce wooden blocks that meet different specifications.

Whether you’re looking to process wooden cubes for pallets or tiles, our wood pallet block machine offers excellent performance and adaptability. Its advanced features and efficient operation make it an ideal choice for businesses seeking to enhance their wood processing capabilities.

How to make pallet blocks with the wood pallet block machine?

To produce pallet blocks using a wood pallet block machine, start by mixing sawdust with glue, typically urea-formaldehyde resin glue at around 16% concentration.

Use a specialized mixer to combine the sawdust or wood shavings thoroughly. Next, evenly feed the well-mixed raw materials into the machine’s feed port.

The machine’s inner screw and hydraulic system work together to push the material into the heating system of its discharge.

A cutting device installed at the discharge port allows you to cut the extruded wood blocks to a desired length.

Pallet blocks with holes VS non-holes pallet blocks

Pallet blocks, whether with holes or non-holes, each have their own distinct features and applications. Here’s a detailed comparison between the two:

Pallet blocks with holes

During the production of pallet blocks with holes, methanol and water vapor can escape through the central longitudinal hole. This unique design gives the wooden cubes good air permeability, preventing them from expanding due to moisture, which in turn helps to extend their service life.

However, when nailing these blocks, it’s crucial to avoid the small round hole in the middle. Otherwise, there’s a risk of the nail accidentally entering the central hole, potentially compromising the structural integrity of the pallet.

Non-holes pallet blocks

Non-holes pallet blocks, as the name suggests, are completely dense with no holes in the middle. This makes them more convenient for nailing, as there’s no risk of nails accidentally entering a hollow space.

The absence of holes also contributes to a more uniform distribution of stress across the block, enhancing the overall stability and load-bearing capacity of the pallet.

The decision to use pallet blocks with holes or non-holes largely depends on the specific requirements of the user. If air permeability and moisture resistance are priorities, then pallet blocks with holes may be the preferred choice. On the other hand, if ease of nailing and maximum load-bearing capacity are more important, non-holes pallet blocks would be more suitable.

In general, the higher the density of the wood cubes, the better their load-bearing capacity, which is a key factor to consider when selecting pallet blocks for different applications.

Parameters of wood pallet block making machine

| Model | Power | Capacity | Dimension | Weight |

| SL-75/2 | 15KW | 3.5m³/d | 75*75*1200mm | 1500kg |

| SL-90/2 | 15KW | 4m³/d | 90*90*1200mm | 1800kg |

| SL-100/2 | 18KW | 5m³/d | 100*100*1200mm | 2000kg |

| SL-120 | 15KW | 3.5m³/d | 100*120*1200mm | 1500kg |

| SL-145 | 18KW | 3.5m³/d | 145*145*1200mm | 1800kg |

Wood pallet block machine video

Common processing sizes of wood pallet blocks

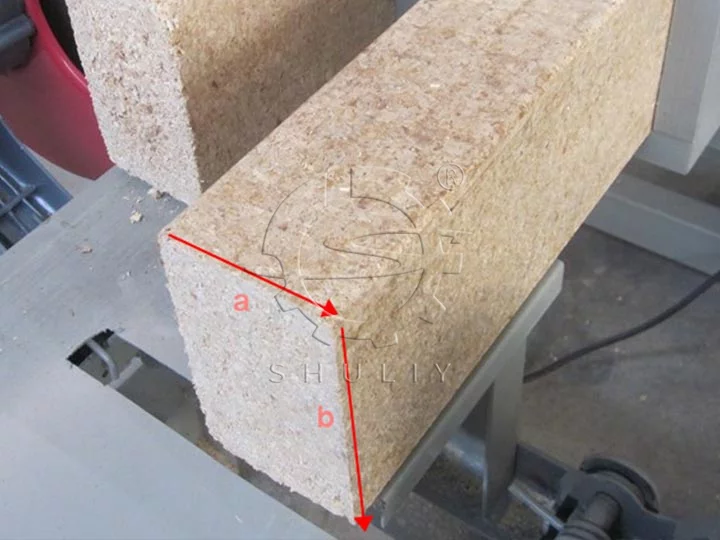

The length of pallet blocks processed by a commercial wood pallet block machine is usually 1200mm. There are usually many cross-sectional dimensions, mainly determined by different molding dies. Common sizes that can be processed are 75*75mm, 80*80mm, 90*90mm, 90*120mm, 100*100mm, 100*120mm, 100*140mm, 100*150mm, 140*140mm, etc. We can also customize the size of pallet blocks according to customer needs.

Wood pallet blocks production line

For customers who need a complete set of pallet blocks processing equipment, we can provide a complete sawdust wood pallet blocks production program, namely the wood pallet blocks production line.

Wood pallet blocks processing line is composed of a series of processing equipment, mainly including hammer mill, sawdust dryer, automatic mixer, wood pallet block machine, and pallet blocks cutting machine.

Sawdust pallet block machine shipped to Indonesia

The industrial sawdust pallet block machine can squeeze rice husks, sawdust, and other raw materials into cubes under high temperature and high-pressure conditions. These sawdust pallet blocks can be further processed into wooden pallet feet.

One of our Indonesian customers ordered a complete set of sawdust pallet block machines from our factory, including a glue mixing machine, pallet block press machine, and pallet blocks cutting machine. The Indonesian customer processed sawdust pallet blocks mainly for selling to specializing in the production of wooden pallets factory.

Conclusion

With its efficient heating system, customizable mold options, and continuous extrusion and cutting design, the Sawdust Wood Pallet Block Machine offers a reliable and scalable solution for producing high-strength pallet blocks from various biomass materials.

Whether you are looking to recycle sawdust or enhance your pallet manufacturing line, this machine delivers consistent output and cost-effective performance.

If you’re seeking a durable, fumigation-free alternative to traditional wooden foot blocks, our pallet block machine is the ideal choice to help you meet both domestic and international packaging standards. Contact us today for more details and customized solutions.